EA Elektro-Automatik EA-PS 11000-80 4U DC Power Supply, Autoranging, Single Output, 1000VDC, 80ADC

Couldn't load pickup availability

Ask an expert!

EA Elektro-Automatik

EA Elektro Automatik is a German manufacturer of programmable power supplies and electronic loads designed for efficiency testing, R&D, and industrial automation.

EA Elektro-Automatik EA-PS 11000-80 4U Programmable Bi-Directional DC Power Supply

DC Power Supply, 1000 VDC, 80 ADC, 30000 W

Wide range input, 208 V - 480 V +10 % 3ph AC

Active Power Factor Correction, typical 0.99

Very high efficiency up to over 96 %

High performance of 30 kW per unit

Flexible power regulated DC output stages (autoranging)

Regulation mode CV, CC, CP, CR with fast crossover

Digital regulation, high resolution with 16bit ADCs and DACs, selection of control speed: Normal, Fast, Slow

Color 5“ TFT display with touch control and intuitive user interface

Galvanically isolated Share-Bus for parallel operation of all power classes in the 10000 series

Programmable Bi-Directional DC Power Supply, Rackmount

The power supplies of the PSB 10000 4U series are so-called bidirectional devices, incorporating the function of a laboratory power supply (source) and an electronic load (sink) into one unit. They allow for easy setup of applications according to the source-sink principle with a minimum of required hardware and cabling. Switching between source and sink operation is seamless and without delay at zero point.

The sink feature furthermore includes an energy recovery function, the same as the one in series ELR 10000, which inverts the consumed DC energy with an efficiency of up to 96% and feeds it back into the local mains.

Apart from the basic functions of power supplies, set point curves can be generated by the integrated function generator (sine, rectangular, triangular, and other curve types). Arbitrary generator curves (99 points) can be saved to and loaded from a USB stick. Some of the functions even offer to dynamically switch between source and sink operation modes by setting up positive (for the source) or negative (for the sink) current set values.

For remote control the devices are provided as standard with USB and Ethernet ports on the rear side, as well as a galvani- cally isolated analog interface. Via optional plug-in interface modules, another digital interface such as RS232, Profibus, ProfiNet, Modbus TCP, CAN, CANopen, or EtherCAT can be added. These enable the devices to be connected to standard industrial buses simply by changing or adding a small module. The configuration, if necessary at all, is simple.

In addition, the devices offer as standard the possibility for parallel connection in so-called Share bus operation for constant current sharing, plus a true master-slave connection with a totaling of all actual values is also provided as standard. Operating in this way allows for up to 64 units to be combined into a single system with a total power of up to 1920 kW.

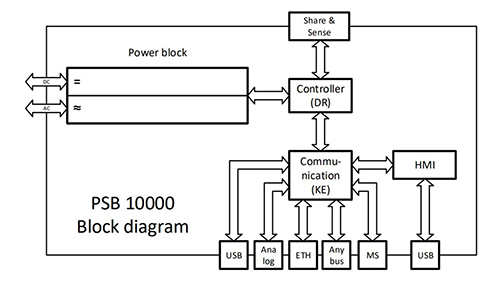

Block Diagram

The block diagram illustrates the main components inside the device and their relationships.

There are digital, microprocessor-controlled components (KE, DR, HMI), which can be a target of firmware updates.

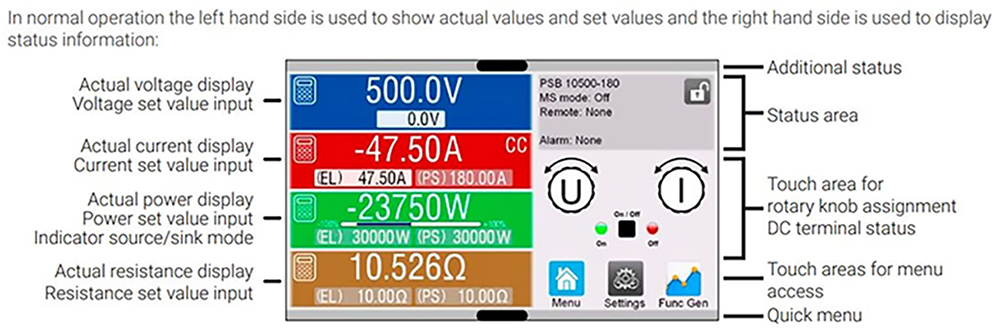

The control panel (HMI)

The HMI (Human Machine Interface) consists of a display with a touchscreen, two rotary knobs, a pushbutton, and a USB port.

Touchscreen Display

The graphic touchscreen display is divided into many areas. The complete display is touch-sensitive and can be operated by finger or stylus to control the equipment.

Rotary Knobs

As long as the device is in manual operation, the two rotary knobs are used to adjust set values in the main screen

The pushbutton function of the knobs

The rotary knobs also have a pushbutton function which is used in all value adjustments to move the cursor by rotation

In The Box

1 x Bidirectional power supply device

2 x Remote sensing plugs

1 x 1.8 m (5.9 ft) USB cable

1 x Set of DC terminal covers

1 x Sense terminal cover

1 x USB stick with documentation and software

1 x AC connector plug (clamp type)

1 x Set for AC cable strain relief