EA Elektro-Automatik EA-PS 10360-40 3U DC Power Supply, Autoranging, Rackmount, Single Output, 360VDC, 40ADC

Couldn't load pickup availability

Ask an expert!

EA Elektro-Automatik

EA Elektro Automatik is a German manufacturer of programmable power supplies and electronic loads designed for efficiency testing, R&D, and industrial automation.

EA Elektro-Automatik EA-PS 10360-40 3U Programmable DC Power Supply

Specs and Features

Voltage 0 to 360 V, Current 0 to 40 A, Power 0 to 5000 W

Wide range input, 208 V - 480 V +10 % 3ph AC

Active Power-Factor-Correction, typical 0.99

Very high efficiency up to over 96 %

High performance of up to 15 kW per unit

Voltage from 0 - 60 V up to 0 - 2000 V

Currents from 0 - 20 A up to 0 - 510 A

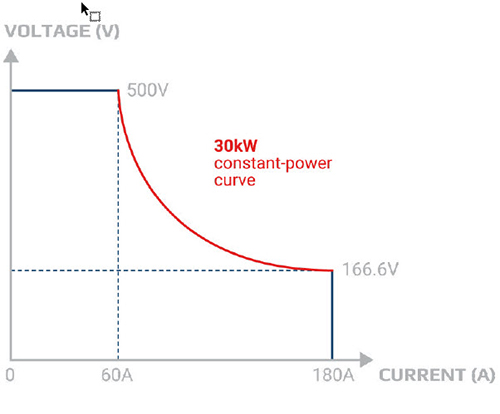

Flexible power regulated DC output stages (autoranging)

Regulation mode CV, CC, CP with fast crossover

Digital regulation, high resolution with 16bit ADCs and DACs, selection of control speed: Normal, Fast, Slow

Color 5“ TFT display with touch control and intuitive user interface

Galvanically isolated Share-Bus for parallel operation of all power classes in the 10000 series

Master-Slave bus for parallel operation of up to 64 units of all power classes in the 10000 series

The DC laboratory power supplies in the PS 10000 series from EA Elektro-Automatik convert the energy from the grid into a regulated DC voltage with an efficiency of over 96%. The PS 10000 series includes single and three-phase units, which, together with the wide input range, allow use with practically all global mains voltages. The DC voltage and current are directed by the application and the spectrum ranges from 0 - 60 V to 0 - 2000 V and from 0 - 6 A up to 0 - 1000 A in a single device. The DC supply operates as a flexible output stage with a constant power characteristic (autoranging), and a wide voltage, current, and power range. To achieve higher power and current all units are equipped with a master-slave bus. This enables up to 64 parallel connected devices to be combined into one system which can provide up to 1920 W and 64000 A. Such a system works as a single unit and can use different power classes, only the voltage class must remain constant. In this way, a user can construct a 75 kW system from two 30 kW and one 15 kW devices from the PS 10000 range. Furthermore, typical laboratory functionality is provided. This includes an extensive function generator, alarm and warning management, assorted interfaces and ports, software solutions, and many more functions.

AC Connection

The DC power supplies in the PS 10000 series are equipped with an active PFC which provides high efficiency at low energy consumption. Furthermore, the devices in this series provide a wide input voltage range. This extends from 1-phase 110/120 V up to 240 V AC mains supply and 3-phase 208 V to 380 V, 400 V, and 480 V AC mains supply. The devices can be operated in the majority of global mains supply. They adjust automatically, without additional configuration, to the available supply. In a 110/120 V and 208 V AC grid, a derating of the output power is set.

DC Output

The output of the bidirectional power supply PS 10000 with a DC voltage of 0 - 60 V up to 0 - 2000 V allows currents of 0 - 6 A up to 0 - 1000 A. The flexible output stages (autoranging) provide the user with a wide voltage, current and power range and hence a wider field of working than traditional power supplies.

DC Connection

Connection of the DC output is via a copper rail on the back side of the device. If a system with higher performance is required. the devices are simply connected in parallel. With minimal effort devices can be linked with the vertical copper rails. A cover for contact protection is provided.

The Principle of Autoranging

“Autoranging“ is a term when a programmable DC Power Supply automatically offers a wide output range of both, voltage and current, to maintain full power across a wide operation range. This type of solution allows the use of a single unit to address multiple voltage and current combinations.

Interfaces

As standard EA devices are fitted with the most important digital and analogue interfaces and ports which are galvanically isolated. These include an analogue interface which can be parameterized for input and output, control and monitoring, of 0 - 5 V or 0 - 10 V for voltage, current, power, and resistance, assorted inputs and outputs as well as USB and ethernet ports.

High-performance Systems

High-power applications can be covered with high-power systems of up to 1920 kW. These are achieved by using the outputs of many PS 10000 devices, changing the copper rails to vertical, and connecting in parallel. Thus, a 19” cabinet with 42 U can provide a system with 240 kW occupying a 0.6 m² floorspace. The master/slave bus enables up to 8 cabinets with a maximum of 64 units of 30 kW each to behave as one unit

Master-Slave-Bus and Share-Bus

If the integral master-slave bus and share bus are used, a multi-device system behaves as a single device. The masterslave bus and the share bus are simply connected to each device. With the master-slave bus, the system data such as total power and total current are collected and shown in the master device. Warnings and alarms of the slave devices are shown clearly on the display. The share bus provides an equal load distribution to the individual devices.

Relay Test in the Production

Relay manufacturers must carry out assorted tests on their products during production. For these, the coils and contacts are provided with exactly defined voltage and current. For the coil tests, important parameters such as operating, holding, and decay current, together with the associated voltages must be checked and documented. For the contacts, not only are the current carrying capability and contact resistance important parameters but also voltage consistency and disconnect threshold indicate much about the product quality. Testing all these is best supported by an automatic test system. A part of such a system can be the devices of the PS 10000 series with their exact, dynamic, controls of voltage, current, power, and resistance, providing optimal values for the best test results. With their diverse interface connections, they can be integrated into any test system and deliver the necessary data without the need for additional measuring equipment.

Onboard Charger Test

In an onboard charger test (OBC) the electrical features must be tested under various conditions. This requires a flexible test system that also provides test data. With the sequencing and logging functions of the PS 10000 devices test procedures allow data to be exported and saved. In this way, applications can promptly generate reproducible test results based on dynamic and highly accurate set point and measurement data. To avoid competition between two separate control loops of the device under test (DUT) and the test device, the control frequency of the power supply is adjustable. The modes Normal, Fast and Slow allow the PS 10000 devices to match the control characteristics of the onboard charger.

In The Box

-

1 x Power Supply Device

-

2 x Remote Sensing Plugs

-

1 x 1.8 m (59 ft) USB Cable

-

1 x Set of DC Terminal Covers

-

1 x Sense Terminal Cover

-

1 x USB Stick with Documentation and Software

-

1 x AC Connector Plug (Clamp Type)

-

1 x Set for AC Cable Strain Relief